Selected Content from Resource Market

Community

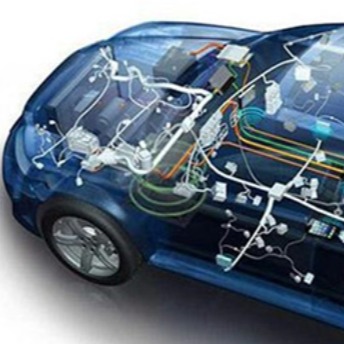

A professional platform for electrical automation practitioners to learn and communicate.Resource Market-Leadsoft Models Repository

Part Models,Schematic Drawings,3D Solutions...All You Need Is Here.